3. ONE

O N E

Prototype Experimental Smart RingAdaptable, modular and functionalONE is a smart ring device that expands on modularity meant to close and merge digital and virtual spaces around the user. The goal of ONE is to give users freedom to access whatever, whenever and wherever.

ONE can be used as a trigger for whatever you set of it when you are out; a calling card, a portfolio website, instruction manual or well wishes. ONE can also be a messenger; triggering items within your household to activate remotely if need be. ONE’s ecosystem also allows you to create RFID triggers around areas you will reside at home to remotely activate other systems.

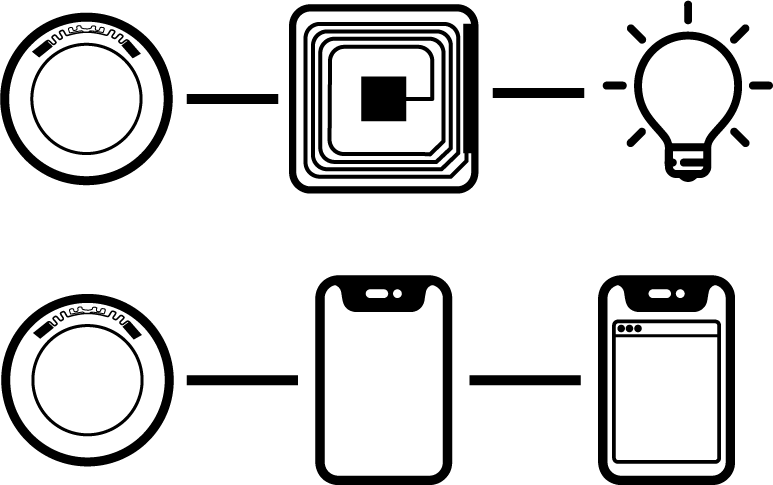

fig 1. ONE is able to activate smart home systems through RFID triggers layed around your house.

fig 2. ONE is also able to open specific web links or control features of phones that are RFID enabled.

How does ONE work?

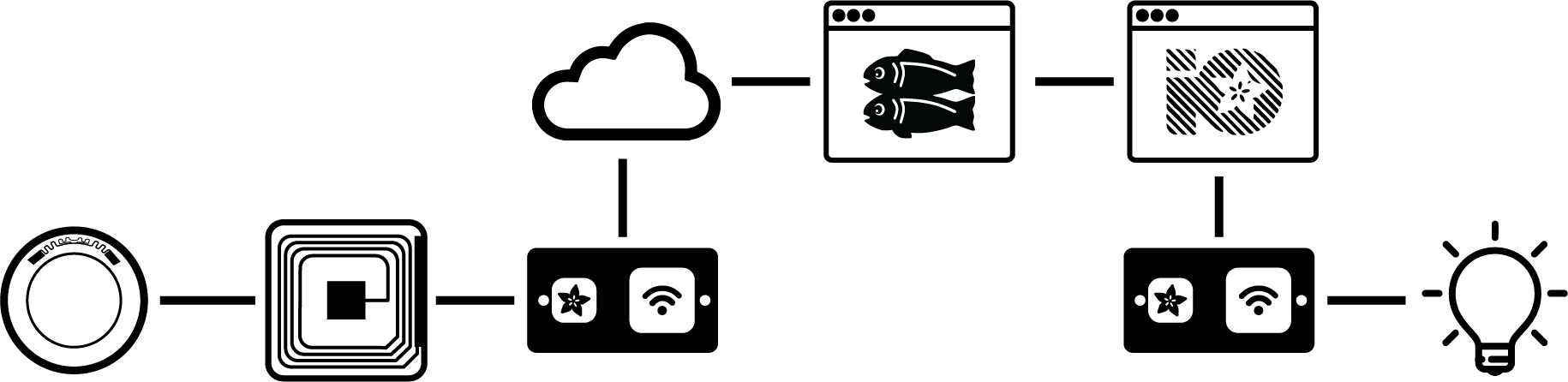

ONE has a passive NFC Tag containing a unique key and a web link.

When the unique key is triggered on your RFID readers placed around your house, they will be trigger a Wi-Fi enabled microprocessor to ping the cloud server set up via Glitch which will ping Adafruit IO's web server that is listening to Glitch. Adafruit IO will send the information to your wifi enabled microprocessor that is hooked up to any device rigged onto it. Lights, cat feeders, air conditioning, anything that starts up if power courses through it.

Form

Because of its extremely small scale and complex curvatures and components, it was impossible to print with any ordinary 3D PLA printer. As a result, I opted to use a SLA Resin Printer from FormLabs. Resin is extremely durable after cured and the way supports are printed with SLA made it easy to remove and smooth for a proper finishing.

The form was intentionally made simple and focused on creating a good fit for the NFC Tag, made to fit by with the smaller outer layer of the ring. The bigger outer layer surrounding the rest of the ring was meant to be filled with glow powder and sealed shut with glue and with 2 tritium vials.

Because of its extremely small scale and complex curvatures and components, it was impossible to print with any ordinary 3D PLA printer. As a result, I opted to use a SLA Resin Printer from FormLabs. Resin is extremely durable after cured and the way supports are printed with SLA made it easy to remove and smooth for a proper finishing.

The form was intentionally made simple and focused on creating a good fit for the NFC Tag, made to fit by with the smaller outer layer of the ring. The bigger outer layer surrounding the rest of the ring was meant to be filled with glow powder and sealed shut with glue and with 2 tritium vials.

︎

︎